Language

DEUTSCH

ENGLISH

Contact

Genan GmbH

46282 Dorsten

Germany

Globally, more than 7 million tyres are scrapped every day. In many parts of the world, they become a waste problem, as they are incinerated or left to degrade in landfill sites, emitting large amounts of CO2. Genan has turned this waste problem into a green opportunity, recycling end-of-life tyres (ELT) for reuse in a variety of ways. As the world’s largest mechanical recycler of end-of-life tyres, Genan’s six global plants have the capacity to recycle up to 150,000 tyres every day reducing CO2 emissions to the atmosphere by 280,000 tonnes a year – the same amount that 100,000 diesel cars emit in one year.

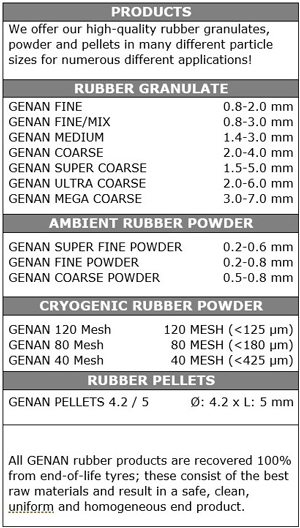

In Genan’s fully automated process, tyres are separated into their initial components: rubber, steel and textile. The end products are uniform and clean – and are therefore well suited for high quality applications: Tyre wire is remelted into new steel. Rubber powder and granulate are used as raw materials by manufacturers that produce things like asphalt, mats, floors, tiles, noise reduction solutions, handles, paint, coatings, and binding agents. Rubber granulate is used as infill in football fields with artificial turf, and both granulate and pellets become the bouncy base layers of playgrounds and running tracks.

Artificial Turf

Impeccable ball behaviour all year round with low maintenance costs

Until the end of the 1990s, artificial turf was mainly used for:

- Tennis courts

- Playing fields for American Football

- Baseball fields

Because ball behaviour and rebound on artificial turf was remarkably different, and because of the increased risk of injury compared to playing on natural turf, artificial turf was not yet considered suitable for major league football.

Since the introduction of the 3rd generation technology, where rubber granulate was used as infill material, artificial turf has been accepted by FIFA and the UEFA – and is admissible for all leagues.

With the use of rubber granulate, the behaviour, rebound and running characteristics of the ball have improved significantly – and the European market for artificial turf has grown rapidly. In comparison to natural turf, artificial turf furthers the development of football in all parts of the world – and its considerably longer use-value makes it an economical solution.

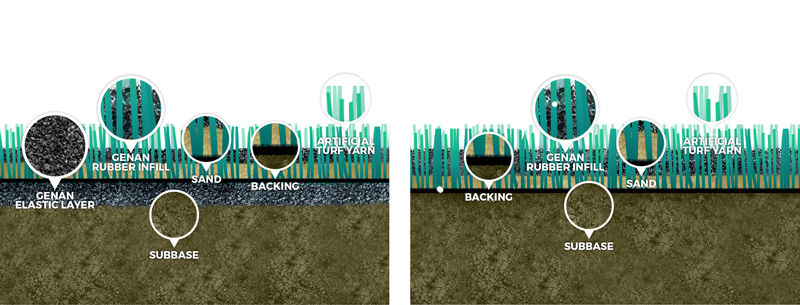

In typical, artificial turf, Genan rubber granulate is used for both the infill layer (GENAN FINE, GENAN FINE/MIX and GENAN MEDIUM) as well as for the construction of the elastic layer, no matter whether it is made on site (in-situ) or from prefab mats.

Infill

Accept no fines, no dust, no smell

Too much dust / fine particles in infill material will smell and dirty clothes and surroundings. This negatively influences both working conditions during the process of laying artificial turf as well as the experience of players and their assessment of the pitch – giving the artificial turf industry a bad image. It is thus important to define strict quality standards for dust / fine particle content.

Genan Infill is almost free from dust and fine particles, and the assessment of players and organisations is thus that it is clean and user-friendly:

- The dust content level is low (as measured according to EN 15051).

- The fine particle content is reduced to a minimum level well below the requirements of DIN 18035-7 (documented through sieve analyses).

Elastic Layer

Long-lasting Elasticity

For artificial turf systems, an elastic base layer is used. Such elastic layer usually consists of rubber granulate and polyurethane binder. For elastic layers, Genan supplies high quality rubber granulate in two sizes: GENAN COARSE and GENAN SUPER COARSE.

An elastic layer can either:

- be constructed on site (in situ), where polyurethane binder is mixed in with rubber granulate, or

- be constructed through the assembly of prefabricated mats.

For elastic layers, GENAN COARSE and GENAN SUPER COARSE granulate are materials of superior quality, as rubber from end-of-life tyres has the best elastic properties in the market – and boasts permanent durability. Through decades of research, the tyre industry has developed an elastic material with a long product life, extremely well suited for this purpose.

STADIAWORLD/Stadionwelt creates company-profiles on behalf of respective companies and exclusively uses the information and contents, which are provided by the company. The respective company is responsible for the content of the presentations on STADIAWORLD/Stadionwelt website (in particular photos, drawings, texts, data, statistics, etc.).